Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

Food and BeverageWhat's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

Many Food Plants, depending upon the types have significant side streams that can be isolated at the point of source and used elsewhere as a by-product or co-product. For example, Beer companies have sent waste beer to make ethanol for fuel for engines. Some food processors send waste food that is low-grade quality to other companies that manufacture animal feed products.

Many food plants do not have waste treatment plants or final effluent discharges and instead discharge directly to a POTW. They usually have some type of pretreatment and then discharge to a local P.O.T.W. Unfortunately, they can sometimes have high connection fees, in addition to surcharges for going over on BOD and TSS. Publicly owned treatment works (POTW) that receive food-processing wastewater with BOD5 values greater than 250 to 300 mg/L typically will add an additional surcharge for treatment. Small changes to the process or additions of small levels of certain chemicals or bacterial products can lower the BOD/COD and TSS created and significantly lower these surcharges. Check out our bioengineering page for more information or request case history examples.

Additional information on the Food and Beverage Industry Links

Water usage at a Food or Beverage facility can be high. Boiler and Cooling Tower Blowdown Oil and Grease- What is it and how to get rid of it Food Plant Wastewater Case Histories Dairy Industry Benchmarks and Case Histories

EPA Office of Compliance Sector Notebook Project, Food and Beverage Industry. More information can be obtained on the EPA website http://es.epa.gov/oeca/sector or

by

contacting Environmental Leverage

Meat Processing Overview Meat processing includes slaughtering, processing, and rendering operations involving primarily cattle, hogs, and poultry. Some plants handle only one type of operation, such as meat processing, but others carry out multiple operations including rendering., smoking, canning, freezing, and sausage making.

With annual sales of nearly $113 billion, the United States produces more

meat for human consumption than any country in the world except China.

A third of all meat processing facilities are located in California,

Illinois, Texas, and New York. This industry has over 1,297 processing

facilities that employ over 88,000 people and produces shipments greater

than $22 billion each year.

The primary avenue for removal of solid waste has been its use in animal

feed, cosmetics, and fertilizers. These solid wastes are high in protein and

nitrogen content. They are excellent sources for recycled fish feed and pet

food. Skeleton remains from meat processing are converted into bonemeal,

which is an excellent source of phosphorus for fertilizers. FOG waste

(typically from industrial fisheries) is used as a base raw material in the

cosmetics industry.

http://www.usaep.org

Solutions: Many times food and beverage plants have

Odor control problems. Did you know that by using biological products as a pretreatment to a P.O.T.W. you can sometimes reduce your surcharge by 50-75% ? Grease, oils, chocolate, food can cause problems in the wastewater treatment plant DAF's of skimming tanks need to be adjusted to handle the solids loading and to capture the grease and oils Screens can be used to prevent solids from entering the treatment plant such as peanuts at a chocolate factory Make sure that if you use a DAF or API, that you optimize all the variables, the skimmer speed and rotation, the oxygen, the flights, the chemicals used, etc.

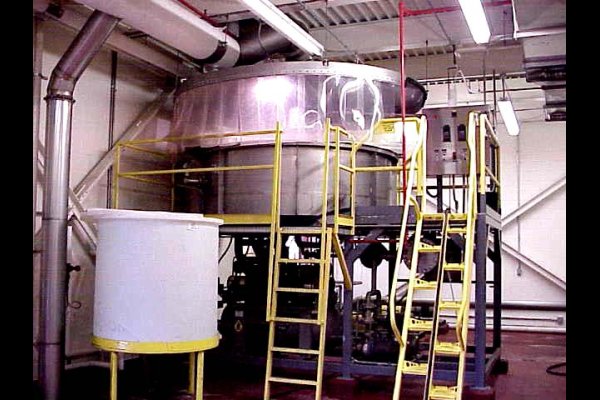

Tanks onsite can be retrofitted or brought in and can be used to pre-treat influent prior to being discharged to a local P.O.T.W. and significantly lower the surcharges that are incurred due to high BOD and TSS fluctuations that often exist at a food and beverage plant. We have worked with a number of plants that used onsite treatment, or small package plants to pretreat their influent and saved 1/2 to one million dollars a year in savings, not to mention headaches and upsets to the local POTW.

In our photoshow above there is a photo of a combination RBC with trickling filter media used at a juice factory. Bioaugmentation with addition of micronutrients helped this plant lower their surcharges to the local POTW by 30-50%.

Did you know most biosolids can be land applied and have significant nutrient value. This can reduce the cost on N and P to the farmer by 30-50% depending upon the values measured in the cake solids and the crop nutrient requirements.

Antifoams- Basic information and when not to use

them

Boiler and Cooling Tower Blowdown

Cooling Tower Microscopic analyses

MicroClear 205 is a powdered product that was developed for use in the

biological wastewater treatment of food based greases, fats and oils. This

product helps digest the fats, oils and grease that can cause problems with

foaming and filamentous bacteria.

Audits and Onsite Training and Consulting

For a full onsite audit of your plant- Contact Environmental Leverage

inc. 630-906-9791

More troubleshooting for Food and Beverage plants:

Troubleshooting Lagoon Systems For a full onsite audit of your plant- Contact Environmental Leverage

inc. 630-906-9791

Bioaugmentation for reduction of BOD and TSS

MicroClear 205 is a powdered product that was developed for use in the

biological wastewater treatment of food based greases, fats and oils. This

product helps digest the fats, oils and grease that can cause problems with

foaming and filamentous bacteria.

Troubleshooting Lagoon Systems

Wastewater in the Fall- Problems and Solutions Lagoons-Winter BOD issues and bioaugmentation Learn how Environmental Leverage can help your plant Bioaugmentation in Food and Beverage plants can impact on BOD and TSS Filamentous bacteria can be a problem is

solids are held too long in a

clarifier also.

More information on grease in

Collection systems and Sewers Collection

systems troubleshooting for Grease and oil Grease and Oil in

Municipalities and Industrial Facilities

Total System Optimization- Case History Lab Testing and Troubleshooting Newsletter More to come . . . . .

Sign up

to receive our Monthly Email Newsletter and be ahead of the curve!

Wastewater Training Options The greatest equipment and the most efficient, dedicated workers can be

ineffective if they are not properly trained. At Environmental Leverage, we

have years of experience in many process areas and technical expertise on

equipment, systems and operations. Programs to optimize your system or

custom training can be tailored to increase the reliability and efficiency

of your plant.

Look

for self taught training materials and training courses below.

We have developed a full line of Training CD's and Elearning classes

for training and operator CEU's.

Elearning and General

Brochure Click for brochure Since wastewater training is such an integral part of any treatment system, we have been asked

to develop an online waste water training program with some of our materials.

Click here and Go straight to our WebSite - www.WastewaterELearning.com Take a sneak peek inside our training courses with our

ELearning

Demo Make sure to create an account and log in.

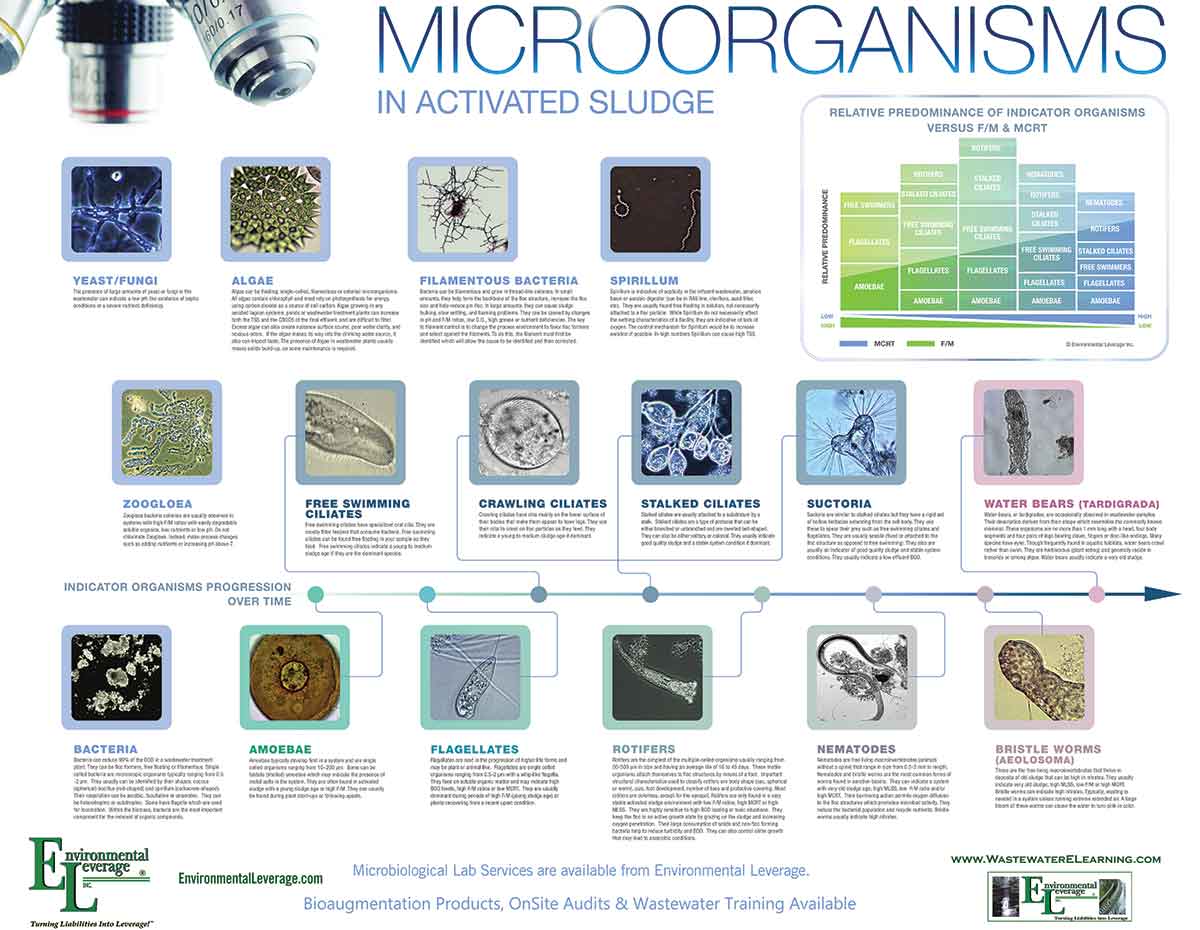

Environmental Leverage Lab Poster

for Wastewater Training. This Microbiology Poster has photos as well as descriptions

and troubleshooting recommendations of common micro organisms found in most

wastewater treatment plants. Contact Environmental Leverage for more

information about obtaining this poster for your lab or setting up hands on

training, consulting and onsite audits.

|

Costs of managing food processing wastes depend heavily on the size and

complexity of the operation. Common waste treatment practices include land

disposal, anaerobic ponds, aerobic ponds, activated sludge, clarifiers and

filtration. Below are some benchmarks: Approximately 90% of a

dairy’s wastewater load is milk. Wastewater volume of "soft drink processes"

is lower than in other food-processing sectors, but fermentation

Costs of managing food processing wastes depend heavily on the size and

complexity of the operation. Common waste treatment practices include land

disposal, anaerobic ponds, aerobic ponds, activated sludge, clarifiers and

filtration. Below are some benchmarks: Approximately 90% of a

dairy’s wastewater load is milk. Wastewater volume of "soft drink processes"

is lower than in other food-processing sectors, but fermentation processes are higher in BOD and overall wastewater volume compared to other

food-processing sectors. Meat, poultry, and seafood facilities offer a more

difficult waste stream to treat. The killing and rendering processes create

blood byproducts and waste streams, which are extremely high in BOD.

processes are higher in BOD and overall wastewater volume compared to other

food-processing sectors. Meat, poultry, and seafood facilities offer a more

difficult waste stream to treat. The killing and rendering processes create

blood byproducts and waste streams, which are extremely high in BOD.

There are tons of files containing information on every subject from A to

Z on the internet with standards, benchmarks and industry BMP's. The

problems is, who has time to dig and find it all. It is not always in easy

to find places. We have tried to show you some of the ones we though

might be useful. There are links to the places where we found some of them

in case you want to dig deeper on a particular subject and find out more.

There are tons of files containing information on every subject from A to

Z on the internet with standards, benchmarks and industry BMP's. The

problems is, who has time to dig and find it all. It is not always in easy

to find places. We have tried to show you some of the ones we though

might be useful. There are links to the places where we found some of them

in case you want to dig deeper on a particular subject and find out more.

Food Plants

Food Plants Watch what color the foam is on your aeration tank if you have one. A

change from brown, to light brown to a crisp white foam can indicate a

recent surge in BOD loading and can significantly impact your treatment

process. Change your wasting rates or RAS or adjust with the use of

bioaugmentation to try to catch up with the F/M loading.

Watch what color the foam is on your aeration tank if you have one. A

change from brown, to light brown to a crisp white foam can indicate a

recent surge in BOD loading and can significantly impact your treatment

process. Change your wasting rates or RAS or adjust with the use of

bioaugmentation to try to catch up with the F/M loading.

In order to "Audit" or Troubleshoot a Food or Beverage

wastewater treatment plant, a number of things need to be looked at. A

physical walk-through of the plant needs to be conducted with visual

observations noted. A microscopic analyses of the Biological portion of the waste treatment

system needs to be conducted. Settleometer Testing needs to be conducted A

sludge judge should be used on a Clarifier Examination of lab data- current

testing procedures and results Walk through and correlation of process side

to wastewater treatment plant operations A fully detailed final report is

issued with process recommendations, system changes, areas for optimization

and increased efficiency.

In order to "Audit" or Troubleshoot a Food or Beverage

wastewater treatment plant, a number of things need to be looked at. A

physical walk-through of the plant needs to be conducted with visual

observations noted. A microscopic analyses of the Biological portion of the waste treatment

system needs to be conducted. Settleometer Testing needs to be conducted A

sludge judge should be used on a Clarifier Examination of lab data- current

testing procedures and results Walk through and correlation of process side

to wastewater treatment plant operations A fully detailed final report is

issued with process recommendations, system changes, areas for optimization

and increased efficiency.