Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

More Case HistoriesLatest News!

What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning Grease Removal in Lift StationsGrease control and lift station maintenance

Lift stations are notorious for filling up with debris, solids and tons of grease. The grease can become hard, form a shelf or ledge, or if too much, almost create a solid layer. By using bacterial products to clean the grease, a long term solution is established for the lift station. The bacteria also benefit the pipes downstream as well as the wastewater treatment plant.

The bacteria actually consume the grease as a food source and permanently remove the grease. Low maintenance dosages can then be used to keep the grease from building up and causing future problems.

This is a 5 Million Gallon a Day lift station that was filled with years of grease build-up.

There were thick solids build up in the corners and all throughout the various tanks. Here is how it looks now after using bacterial products to degrade the grease.

Except for a little bit of solids in the upper left corner, most of the grease and solids build-up are gone. Here is the upper right corner- clean and free flowing water as opposed to the above picture prior to addition of our biological products. The grease ledge is gone, the solids and chucks of grease are dissolved and there is circulation of water and better mixing. Bacteria are used to slowly degrade the grease and solids build up as opposed to chemicals that send grease down the collections system and to the wastewater treatment plant.

Find out how you can start your Grease Removal Program today or email us Texas Barbecue Restaurant and Package plant

Before and After Bioaugmentation We were asked to help with foaming and grease problems at a small package plant that handled wastewater from a Texas Barbecue Restaurant.

A dual program using liquid concentrated product upstream at the restaurant in the wet wells and using dried bacteria and micronutrients at the wastewater treatment plant eliminated all of the foaming problems.

More information Tank Remediation at a Petrochemical Plant

The plant started the program and had the tank cleaned up in less than three weeks, yet the tank had been sitting there filled for over three years. They were tremendously impressed. They would have spent hundreds of thousands of dollars to haul out the waste.

Tank remediation is not really that hard. As long as the contents are organic, it is actually quite simple. To the bacteria, it is just food. Since the waste stream is already isolated, it becomes just a time and numbers game with the right species of bacteria. Inoculate the tank with bacteria, make sure the critical 5 are in place- (pH, D.O., temperature, N and P) and watch them go to work!

It does not really take long depending upon how much you seed the tank with. And the bacteria grow and multiply exponentially, so just sit back and wait. You wind up with a clean tank, clear effluent, and some bacteria residuals on the bottom of the tank that need to be disposed of- ( usually sent to the plants onsite dewatering system) or land applied.

Operator training, System optimization- Dairy processing wastewater treatment plantAudit Case History at a Dairy processing plant- Milk and Yogurt

This plant did what we recommended though. The biggest benefit was the settling to the clarifier in the cold months. The 1/2 hour SVI had over a 62% reduction from 740 ml in the settleometer down to 280! This made a difference in solids handling also! What a simple fix, just add nutrients!!!!!!

Nutrient Optimization-How important are nutrients

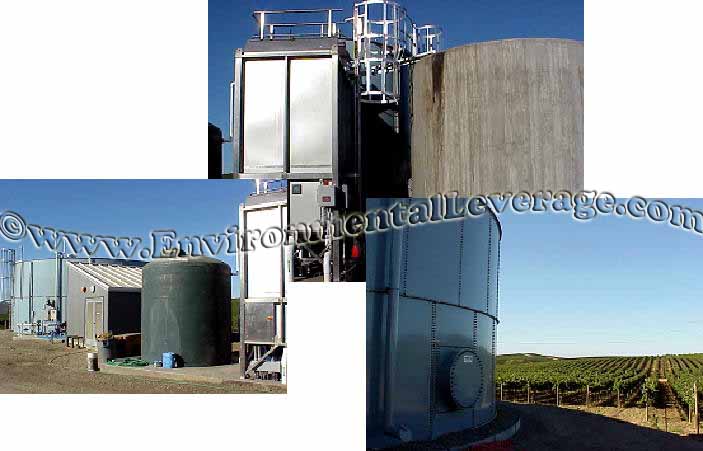

Winery Start-up of a new wastewater plant

By using biological products, you can shorten the time for start-ups and increase the MLSS and get the plant up and running quickly.

There are things to watch when starting up a plant though, as serious white foaming can be a problem and levels must be monitored.

Holding tank- Bioaugmentation treatment program in PakistanCapacity 1m3/Hr pH 2.8 Temperature 90-95 degree c Acetaldehyde 2300ppm EG (mono-ethylene glycol) 150000ppm 2,methyle 1-1, 3 dioxane 260ppm Dioxane 140ppm Acetic Acid 110ppm COD varies from 20000ppm to 30000ppm Target COD is 10000ppm.

This tank has two sections, with approximate holding time of 55 hours. Its pH is adjusted by using caustic to the range pH 7.0. And temperature is also lowered by air stripping before hanging the brick. This also helps to remove VOC’s from the wastewater. . The retention time of the tank is about 55 hours.

Influent COD was 39000 at the start. After hanging Biobricks in the system, effluent COD was 19200 for the outlet in only 24 hours, a reduction of 51%. Nutrients were not added until the second day, and the effluent dropped again to 15380. Third day- 13000 from a start of 3900 in a tank in such a short time!!!!.

Additional pH adjustment and mixing, along with nutrient additions were recommended, but for first time results, this is actually quite amazing! Soil Remediation Case HistoryIndustrial Zone Alon Tavor Israel Plant Issues

But some plants have constantly changing influents. No matter how great a control they have, their biomass is in constant flux. Sometimes adding a biological product or micronutrients can help stabilize and increase the efficiency of the biomass. Click on this link for our MicroClear & MicroSolv bacterial product line catalog.

Bioaugmentation Benefits Key Benefits

Biological Products by Application

**Bioaugmentation Programs include technical support, computer based training and long term programs include occasional complimentary Wastewater Biomass Analyses of your system.

Links to Additional Troublehsooting Pages For More information on Products:Biological Products, Descriptions, Usage and Applications Wastewater Case HistoriesBiological Products for use in Wastewater Applications for Bioengineering and Bioaugmentation

Biological Wastewater Treatment Products

How are your bugs doing?

|

.jpg)

This

plant did not have too many problems running, but the SVI's were a bit high

and they did spend a bit on polymer to dewater sludge. Solids handling were

limited during the winter, due to the fact that land application of the

sludge was required.

This

plant did not have too many problems running, but the SVI's were a bit high

and they did spend a bit on polymer to dewater sludge. Solids handling were

limited during the winter, due to the fact that land application of the

sludge was required.  We

were asked to provide products for a brand new winery start-up. We started

them on a dual program with bacterial product-

We

were asked to provide products for a brand new winery start-up. We started

them on a dual program with bacterial product-